PRESERVING RAILROAD HISTORY IN AMERICA’S HEARTLAND

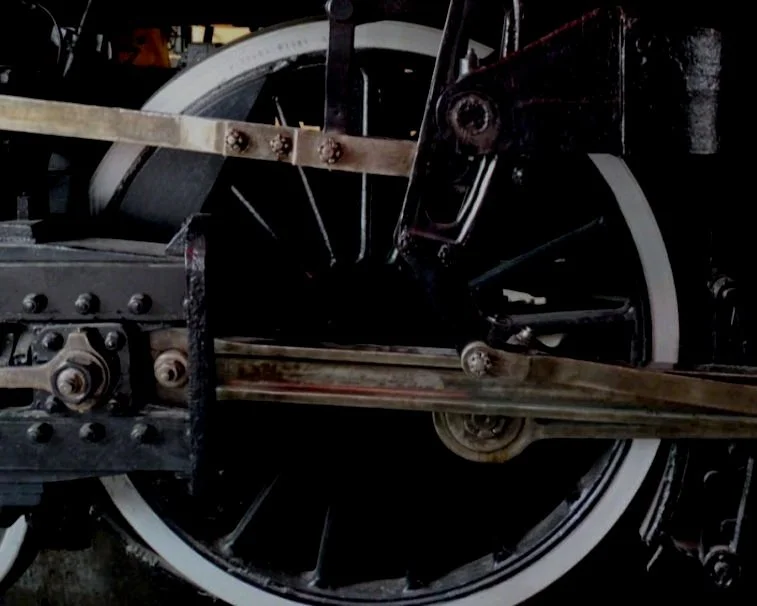

Photo by Ty Smith

AMERICAN HEARTLAND RAILROAD SOCIETY

The American Heartland Railroad Society (AHRS) is a 501(c)(3) non-profit organization founded in 2024 with a singular mission: To preserve railroad history across America’s Heartland.

With a dedicated team of over 40 volunteers, we are combining skills and expertise from all different walks of life to keep the stories of American railroads alive and breathing in the 21st century.

OUR PROGRESS

-

G.N. 1355’s NYAB No. 5 Duplex compressor needed its piston rings and piston rods replaced, as they were damaged.

Fortunately, the Kandiyohi County Historical Society in Willmar, MN, has G.N. 2523, a P-2 class mountain type with two of the same air compressors. The historical society generously agreed to let us remove these compressors, tear them down for parts, and return cosmetically identical compressors to the locomotive.

You can learn more about G.N. 2523 and the organization here: http://www.kandiyohicountyhistory.com/engine.html.

Volunteers from the AHRS were sent up to Willmar to meet with the director of the historical society, where the agreement was made. Both compressors were carefully removed and transported to our shop in Sioux City, IA. While G.N. 2523 has been sitting outside since the 1960s, the addition of an overhead structure to protect the locomotive from the worst of nature's fury has kept this locomotive in amazing condition. In all, we were able to safely remove both compressors and the governor for use on our project.

-

The superheater tubes from G.N. 1355 have been removed and organized for testing.

The process of cutting out the tubes and flues from the boiler has officially begun. Thanks to our friends at the Boone & Scenic Valley Railroad & Museum for their help in guiding us through this process.

The air compressor has been fully disassembled, and parts needing repair/replacing have been identified.

The main reservoirs have lowered from the locomotive and are being prepped for their thickness testing.

The locomotive was turned in an effort to minimize the impact that the tube removal process has on the museum's day-to-day operation.

-

Volunteers kicked off the day with a hearty breakfast before getting straight to work. The first task was moving the Baldwin-built 2-6-2 Florida and Alabama No. 18 to clear space for G.N. 1355’s tender, allowing inspection work to begin.

Next on the docket was moving 1355 herself out of the shop for the morning. Once in position, volunteers carefully removed her sand dome and petticoat, both of which were safely placed into storage until next required.

The day's work concluded with the separation of the locomotive from its tender. Volunteers also began labeling the superheaters and carefully started the process of removing them.

-

After 33 years of faithfully lighting the way, G.N. 1355’s headlight was carefully removed from the smokebox door and lowered to the floor. Immediately afterward, the smokebox door itself was detached. This delicate and essential task was carried out with care by volunteers Jacob Hildreth and Trevor Ruffcorn.

The next order of business was to loosen all the bolts securing the smokebox front plate to the locomotive. With enough volunteers on hand to safely manage the task, the team secured the plate to the A-frame crane. Under the careful supervision of President Logan Stilwill, the plate was gently lifted free and made its safe descent to the ground.

Now, it rests proudly on display beside G.N. 1355’s headlight, smokebox door, and bell, and now the general public now has a unique opportunity to view the inside of 1355.

-

As the snow finally began to let up, the new year was ushered in with the first work weekend of the season. January’s and february’s workdays began with volunteers gathering to reacquaint themselves and welcome new faces.

With lighter tasks on the docket, volunteer Ian Vondrak and Sioux City Railroad Museum volunteer Cody Foreman set to work gridding G.N. 1355’s boiler for the ultrasound test with various degrees of success, as initial chalk guidelines proved to be misaligned. But after a good lunch and a bit of fenagling, the issue was sorted out, and work resumed with better results.

Meanwhile, Jacob Hildreth focused on disassembling the Alco Type K power reverser. At the same time, Chris Strawn and Joe Korpiewski turned their efforts to the tender, working to remove the water inlet line.

The locomotive’s dynamo was removed and underwent a preliminary test. To our pleasant surprise, it was in good condition, as it had not been used since the mid 1950s.